3 Design Mistakes to Avoid When Manufacturing Springs

2 CommentsDesign mistakes during spring manufacturing can get costly, especially when the mistake is reproduced across a high-volume production run.

These mistakes can also cost valuable time and money in the form of recalls, redesigns, and repeat production.

These mistakes can also cost valuable time and money in the form of recalls, redesigns, and repeat production.

As a spring manufacturer, we’ll often share the following feedback to help our clients save time and money and avoid design mistakes. Here are some of the most common mistakes we come across:

1. Bend Radius is Too Tight

Bends cannot be too close to an edge or the material on either side of the bend may tear. This can have a severe impact on the integrity of the spring. The design must also account for material type, tooling, and the bending method to ensure that springback can be accurately predicted.

Springback is a natural reaction by the material as it attempts to return to its flat shape. Accounting for springback in the design is essential to determining the proper bending angle. Springback becomes even more difficult to compensate for in profound radius bends—bends where the bend radius exceeds the thickness of the material by a factor of 10 or more. Tears resulting from tight radii can be compensated for by offsetting the edge with extra material to even out the ratio between the bend radius and the material thickness.

2. Wrong Material Is Chosen

Material selection represents a critical point in the design process. A variety of application-specific factors must be accounted for when choosing a material from which to fabricate a spring design. Some of these factors may include:

- Temperature

- Stress

- Corrosion

- Magnetism

- Conductivity

Having springs developed from appropriate materials that will function optimally in the intended environment will ensure their integrity and extend their service life. Some of the most popular materials include:

Stainless Steel

In the medical field, stainless steel is one of the most popular material choices for springs because of its resistance to uncommon temperatures, high corrosion resistance, and inexpensiveness.

Alloy Steel Wire

Alloy steel wire can function in moderately high temperatures, and is particularly useful under high-stress conditions. This makes it an ideal solution for applications where impact loading or frequent shock may occur.

High Carbon Wire

One of the most affordable materials, high carbon wire is more suitable for protected environments, as carbon corrodes if it is not lubricated or not sealed atmospherically.

Inconel Wire

For environments that have both high temperature and high corrosion potentials, Inconel wire offers an ideal solution for spring manufacturing. These properties make Inconel a material of choice for the aerospace sector.

3. Requesting the Wrong End Types

A thorough understanding of the end types available for springs helps custom projects progress faster. End types are a critical factor in an industrial spring’s design, along with index, number of coils, direction of coiling, stress, etc.

Below are some of the available types of ends available to manufacturers:

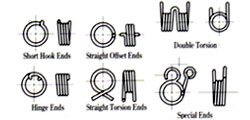

- Torsion spring end: Torsion springs function by resisting and reversing the rotary motion of the components they are attached to. Torsion spring ends typically feature only one type of end, which is a straight piece of wire known as a leg.

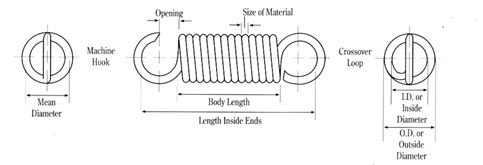

- Extension spring end: Extension springs begin operation in a compressed state before being pulled apart. As such, available ends are typically a form of hook or hoop to facilitate connection to machinery or other equipment. The end types may include open ends, double closed, closed and ground, and closed and squared.

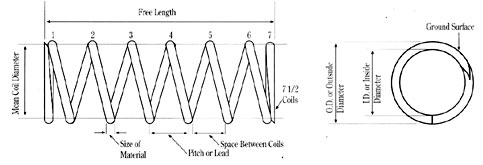

- Compression spring end: The most common spring type, compression springs leave spacing between the final two coils to resist force applied by loads or shock. Depending on the spring and its function, optional ends may be closed and ground, closed and squared, double closed, or in some cases open ends.

Working with Spring Manufacturing

Engaging an experienced spring manufacturer to assist with the design and fabrication of your standard or custom spring solutions can mean the difference between a failed or successful production run.

Since our founding in 1979, Spring Manufacturing has specialized in the design and fabrication of springs of all types and has helped businesses across all markets. For more information on how we can help you with your spring needs, don’t hesitate to contact us.