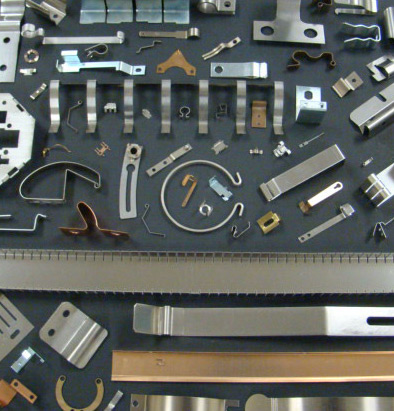

At Spring Manufacturing Corporation, we are experts at delivering custom flat forms for a wide variety of applications. Our flat forms, which can exist as springs, clips, leaf springs, contacts, stampings or other products, can be from both conventional and custom materials, specializing in small quantities to large runs.

We are able to manufacture flat forms with tight tolerances according to your exact design needs. By focusing on the requirements of the flat form’s application, we can help specify the final shape, size, material type and thickness. This way we can create a final product that satisfies any functional or wear challenge.

Different materials allow for rust inhibiting, high stress, working in high or low temperatures, tighter bend radii, and other design advantages. We make flat forms in a wide variety of materials to ensure maximum flexibility. Some of our build materials include beryllium copper, stainless, Inconel, and Titanium.

Our high quality flat forms are a product of our focus in our niche market. We are able to provide a level of flexibility with standard tooling, laser cutting, and chemical etching services that other spring and form fabricators cannot match. Feel free to contact us directly to learn more about our flat form production.

Flat Form Spring Materials

- Stainless 301, 316, 321, 17-7 Condition C, Annealed, ½ hard, ¼ Hard, ¾ Hard, High Yield

- Beryllium Copper

- Aluminum

- Annealed Spring Steel

- Blue Tempered

- Brass

- Inconel

- Monel

- Phospher Bronze

- Titanium