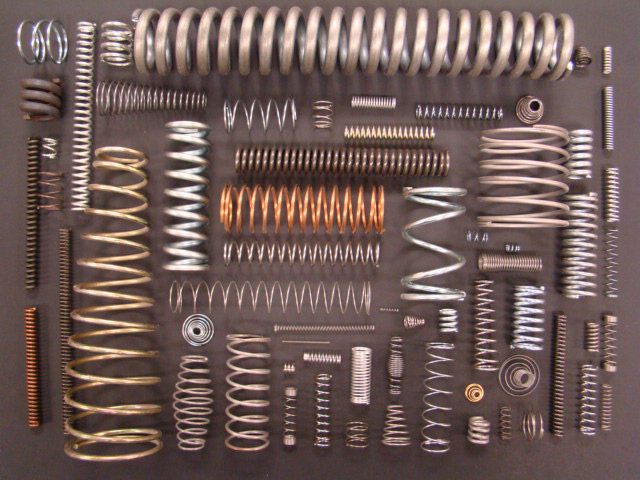

At Spring Manufacturing Corporation, we fabricate springs that are durable, precise, and cost-effective. Our specialization in compression springs allows us to manufacture in exotic materials, in small to large volumes, with tight tolerances – capabilities not found with other spring manufacturers.

We provide our customers diversity in spring design manufacturability producing standard compression springs or special types such as conical, barrel, hourglass, variable pitch, rectangular wire, and nested springs. Our fabrication equipment is able to work with any of these designs creating a spring with many load requirements or dimensional constraints.

Many factors are considered when we design a compression spring. Some examples include the type of material, spring index, free length, type of ends, number of coils, solid height, direction of coiling, squareness, spring rate, stress, loads, rate, buckling, packaging and number other factors. Ultimately the customer’s planned application for a compression spring decides these values, and most importantly, the type of material the spring uses. We are able to fabricate springs in common materials, such as stainless or music wire, as well as exotics such as Inconel, Monel, Hastelloy, copper alloy, and other materials for your designs working environment.

In designing compression springs it is not just the numbers that add up to a good plan, it’s also the knowledge and experience we offer in manufacturing our products. Feel free to contact us directly for more information.

Compression Spring Materials

- Stainless 302, 316, 17-7

- Music

- Beryllium Copper

- Brass

- Chrome Silicon, Vanadium

- Elgiloy

- Hastelloy

- Hard Drawn

- Inconel

- Monel

- Oil Tempered

- Phospher Bronze

- Titanium

- Tungsten