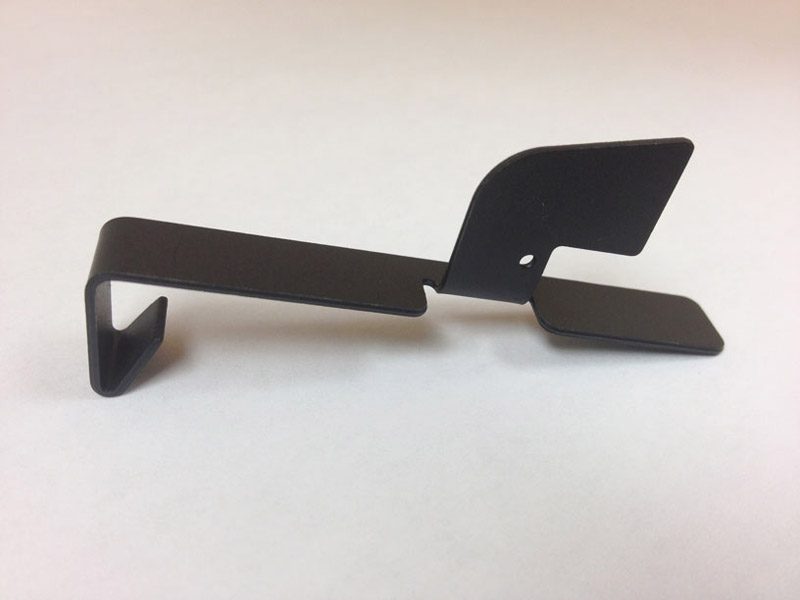

A customer in the medical industry commissioned Spring Manufacturing to provide design assistance during the design phase of a latch slide spring clip project. This part was to be used in a heart pump battery pack. We analyzed the application criteria in order to advise on material selection and to determine the ideal finishing techniques. We designed and fabricated the custom tooling for the part, utilizing standard tooling and pneumatic presses to form the specified bends while maintaining a ±0.005″ tolerance. Composed of 17-7 condition A stainless steel, the .035″ thick part was subjected to the annealing and tempering process to meet the TH 1050 hardness condition. The part was finished in a black PTFE coating.

Turnaround time for this project was 8 weeks, fabricating 1,000 to 15,000 units per order for shipping throughout the United States and Mexico. Our services were also procured for the fabrication of inspection tools for this part, in order to preserve the customer’s 100% inspection model in a cost effective manner. This part has since been passed on to an assembly house, to accommodate growing production levels. For more details about this latch slide spring clip manufacturing project, or our other custom spring design and fabrication capabilities please see the table below or contact us directly.

Stainless Steel Latch Slide Spring Clip Project Highlights

- Project Name

- Latch Slide Spring Clip

- Project Description

- This stainless steel 17-7 latch slide spring clip is used in a heart pump battery pack.

- Capabilities Applied/Processes

- Primary:

Tooling Design

Spring Forming

Plating

- Tightest Tolerance

- +/- .005

- Material Size

- .035 Thick, Chemically Etched Part

- Material Used

- Stainless Steel 17-7 condition A, Tempered to TH 1050

- Material Finish

- Black PTFE

- Industry for Use

- Medical

- Volume

- 1,000 to 15,000 pieces per order

- Delivery Time

- 8 weeks

- Delivery Location

- United States, Mexico

- Standards Met

- Customer blueprint standards