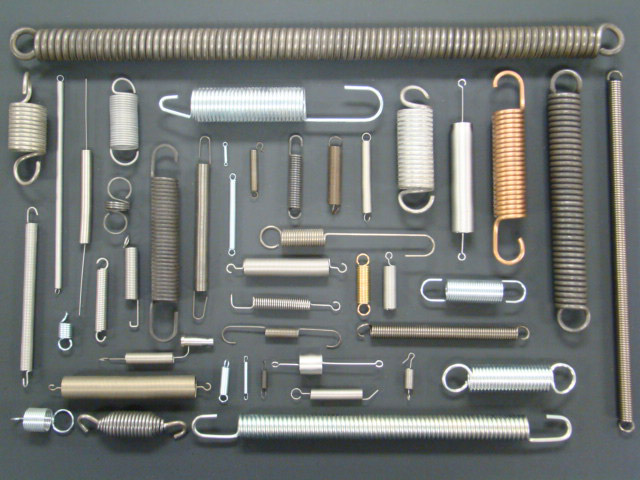

At Spring Manufacturing Corporation, we invite customers to discover the benefits of sourcing their extension springs from a company committed to the design and manufacturability of your product. Our focus on springs allows us to deliver custom designs and low to high volume orders in common and exotic materials.

We consider many factors when designing an extension spring: spatial requirements, initial tension, type of ends, coil direction, and stress levels. We place material consideration as a top priority in extension spring design. Our ability to fabricate springs with unconventional materials allows us to design springs built for exact applications, satisfying your endurance and environment requirements. Some of our build materials include stainless steel 302, 316, 17-7, as well as Inconel, music/piano wire, Monel, beryllium copper, and Tungsten.

In designing extension springs it is the knowledge and experience used that makes a quality product. Our longtime focus on niche market springs means that we have more specialized knowledge and experience to offer than other spring producers. Feel free to contact directly to learn more or request a quote.

Extension Spring Materials

- Stainless 302, 316, 17-7

- Music

- Beryllium Copper

- Brass

- Chrome Silicon, Vanadium

- Elgiloy

- Hastelloy

- Hard Drawn

- Inconel

- Monel

- Oil Tempered

- Phospher Bronze

- Titanium

- Tungsten